LPG Series High-Speed Centrifugal Spray Dryer For Sale

Descriptions

The Spray drying is the technology most widely used in the liquid technology shaping and in the drying industry. The drying technology is most suitable for producing solid powder or particle products from liquid materials, such as: solution, emulsion, suspension and pumpable paste states, for this reason, when the particle size and distribution of the final products, residual water contents, mass density and the particle shape must meet the precise standard, spray drying is one of the most desired technologies.

Video

The LPG series spray dryer uses a high-speed centrifugal atomizer to ensure rapid and uniform drying of liquid materials. This innovative design atomizes the feed liquid into fine droplets, which are then instantly dried by hot air flow. The result is a fine and uniform powder without any fragments or clumps.

One of the main features of the LPG series spray dryers is their excellent drying efficiency. The hot air flow generated by the equipment reaches high temperatures and effectively evaporates the moisture in the liquid feed. This significantly reduces drying time, making it ideal for time-sensitive production processes. Additionally, adjustable drying temperatures and airflow rates provide maximum control over drying conditions, ensuring optimal results for every application.

The LPG Series Spray Dryer also features a user-friendly control system for easy operation and monitoring. Equipped with advanced sensors and indicators, operators can easily adjust and monitor drying parameters, ensuring consistent and precise drying performance. This dryer also features a sturdy construction with high-quality materials that are resistant to corrosion and wear, ensuring long-term durability and minimal maintenance requirements.

This high-speed centrifugal spray dryer is suitable for a variety of liquid materials, including pharmaceuticals, food ingredients, compounds, ceramics, and more. It efficiently dries solutions, emulsions, suspensions and other liquid forms, resulting in ready-to-use powders that meet the highest quality standards.

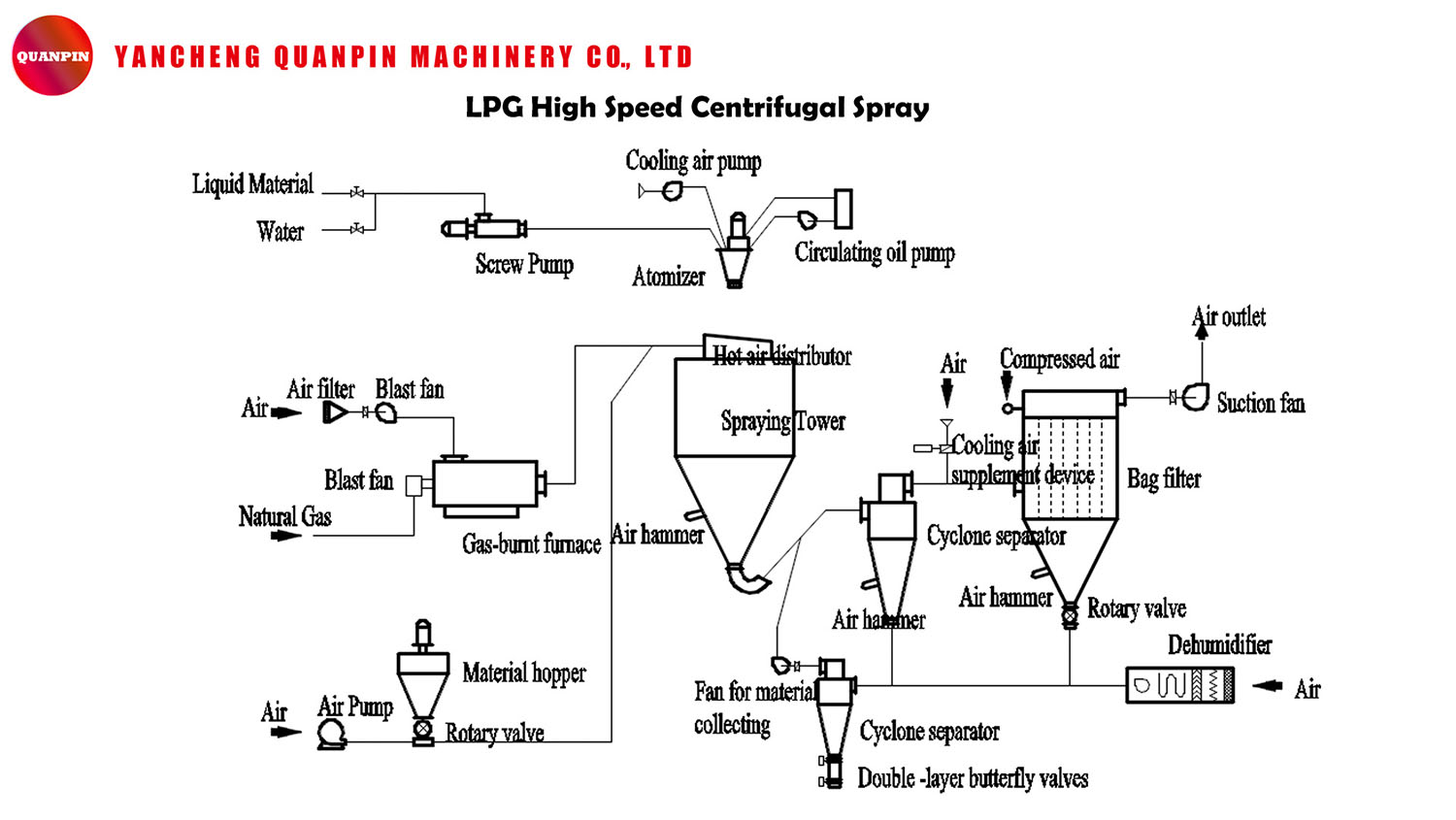

Working Principle

Spray Dryer for the open cycle and flow, centrifugal atomization. After air drying medium early, medium efficiency air filters and filtered according to the operating instructions by the draw and then heated by the heater blower high efficient filter through into the hot air dispenser spray drying the main tower. After the liquid material in accordance with an operation instruction peristaltic pump, atomizer into the high-speed rotation, the centrifugal force is dispersed into small droplets. In Spray drying main tower with hot air in small droplets full contact drying by heat exchange with a product along a particular path, then through a cyclone to achieve separation, the solid material is collected, filtered and then the gaseous medium, and then discharged. Spray the entire system easy to clean, no dead ends, in line with GMP requirements.

Points:

1. The contact with the hot air droplets: a sufficient amount of hot air entering Spray drying chamber must be considered hot gas flow direction and angle, and whether it is flow, countercurrent or mixed flow, to ensure full contact with the droplet can be sufficient heat exchange.

2. Spray: Spray Dryer atomizer system must ensure a uniform droplet size distribution, which is essential. Because in order to ensure that the passing rate of product quality.

3. And the angle of the cone angle of the pipeline design: We get some empirical data from the production of nearly a thousand units Spray Dryer group, and we can share.

Feature:

1. Spray drying speed, when the material liquid is atomized, the surface area increased significantly, with the hot air in contact with the process, the moment can be 95% -98% moisture evaporation, drying time of just a few seconds, especially for heat-sensitive materials dry.

2. The product has a good uniformity, higher fluidity and solubility, purity and good quality.

3. Spray Dryer production process is simplified, easy to operate controls. For moisture content of 40-60% (for special materials, up to 90%) of the liquid can be dried into a powder product, after drying without crushing and screening to reduce the production processes, improve product purity. For the size, bulk density, moisture, within a certain range can be adjusted by changing the operating conditions, the control and management is very convenient.

Technical Parameter

| Model/Item | 5 | 25 | 50 | 100 | 150 | 200 | 500 | 800 | 1000 | 2000 | 3000 | 4500 | 6500 | ||

| inlet air temperature(°C) | 140-350 Automatic Control | ||||||||||||||

| output air temperature(°C) | 80-90 | ||||||||||||||

| Atomizing way | High speed centrifugal atomizer (mechanical transmission) | ||||||||||||||

| Water evaporation upper limit (kg/h) |

5 | 25 | 50 | 100 | 150 | 200 | 500 | 800 | 1000 | 2000 | 3000 | 4500 | 6500 | ||

| Speed upper limit (rpm) | 25000 | 22000 | 21500 | 18000 | 16000 | 12000-13000 | 11000-12000 | ||||||||

| Spray disc diameter (mm) | 60 | 120 | 150 | 180-210 | According to the requiremet of technical process | ||||||||||

| heat source | Electricity | steam + electricity | Steam + electricity, fuel oil, gas, hot blast stove | ||||||||||||

| Electric heating power upper limit (kw) |

12 | 31.5 | 60 | 81 | 99 | Using other heat source | |||||||||

| Dimensions (L×W×H) (m) | 1.6×1.1×1.75 | 4×2.7×4.5 | 4.5×2.8×5.5 | 5.2×3.5×6.7 | 7×5.5×7.2 | 7.5×6×8 | 12.5×8×10 | 13.5×12×11 | 14.5×14×15 | Determined according to the actual situation | |||||

| Powder product recovery rate |

About 95% | ||||||||||||||

Brief

Spray Dryer, Spray drying tower is liquid forming process and drying process industry is the most widely used. Most suitable for the production of powder from suspension emulsions, solutions, emulsions and paste liquid, granular solid product. Thus, when the finished product particle size distribution, residual moisture content, bulk density and particle shape are in line with the precision standard, Spray Dryer is ideal for drying process.

Flow Chart

Application

Chemical products: PAC, disperse dyes, reactive dyes, organic catalysts, silica, washing powder, zinc sulfate, silica, sodium silicate, potassium fluoride, calcium carbonate, potassium sulfate, inorganic catalysts, each and other kinds of waste.

Food: amino acids, vitamins, eggs, flour, bone meal, spices, protein, milk powder, blood meal, soy flour, coffee, tea, glucose, potassium sorbate, pectin, flavors and fragrances, vegetable juice, yeast, starch, etc.

Ceramics: Alumina, zirconia, magnesia, titania, titanium, magnesium, kaolin, clay, various ferrites and metal oxides.

QUANPIN Dryer Granulator Mixer

YANCHENG QUANPIN MACHINERY CO., LTD.

A professional manufacturer focusing on the research, development and manufacture of drying equipment, granulator equipment, mixer equipment, crusher or sieve equipment.

Currently, our major products include capacity of various types of drying, granulating, crushing, mixing, concentrating and extracting equipment reaches more than 1,000 sets. With rich experience and strict quality.

https://www.quanpinmachine.com/

https://quanpindrying.en.alibaba.com/

Mobile Phone:+86 19850785582

WhatApp:+8615921493205