Maternal Liquid Drying And Evaporation Machine

Video

Maternal Liquid Drying And Evaporation Machine is a kind of internal heat conduction type rotating drying equipment independently researched and developed by Yancheng City Quanpin Drying, the wet material obtains the heat transferred by thermal conductivity on the outer wall of the drum, removes the water and achieves the required wet water content. Heat is transferred from the inner wall of the cylinder to the outer wall of the cylinder, and then through the material film, its high thermal efficiency, can be operated continuously, so it is widely used in the drying of liquid materials or strip materials, Yancheng City, Quanpin Machinery's mother liquor drying evaporation of the machine is more suitable for paste and viscous materials.

Features

(1) High thermal efficiency:

The heat supplied in the cylinder, in addition to a small amount of heat radiation and the end cover of the cylinder body part of the heat loss, most of the heat is used in the wet part of the gasification, the thermal efficiency can be as high as 70~80%.

(2) Drying rate is large:

The heat and mass transfer process of the wet material film on the cylinder wall, from inside to outside, in the same direction, the temperature gradient is large, so that the material film surface to maintain a high evaporation intensity, generally up to 30~70kg.H₂O/m².h.

(3) The drying quality of the product is stable:

Roller heating mode is easy to control, the temperature inside the cylinder and the heat transfer rate of the wall can be kept relatively stable, so that the material film can be dried in a stable state of heat transfer, and the quality of the product can be guaranteed.

(4) Wide range of application:

The liquid phase material using drum drying, must have mobility, adhesion and thermal stability of the form of the material can be a solution, non-homogeneous suspension, emulsion, sol-gel and so on. For pulp, textiles, celluloid and other band materials can also be used.

(5) the production capacity of a single machine:

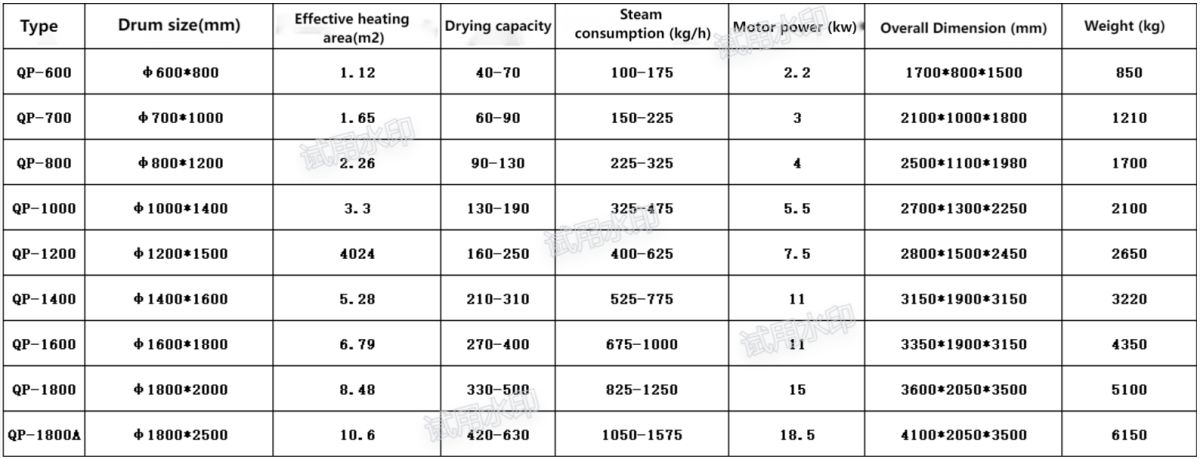

Restricted by the size of the cylinder General drum dryer drying area, should not be too large. The drying area of a single cylinder, rarely more than 12 m2. The same specifications of the equipment, the ability to deal with the liquid material, but also by the nature of the liquid material, moisture content control, film thickness, drum speed and other factors, the magnitude of the change is large, generally in the range of 50 to 2000kg / h. The drying area of a single cylinder, seldom more than 12m2.

(6) heating medium is simple:

Commonly used saturated water vapour, pressure range of 2~6kgf/com2, rarely more than 8kgf/cm2. For some of the requirements of drying materials at low temperatures, hot water can be taken as a heat medium: to dry materials at higher temperatures, can also be used as a heat medium or high-boiling organic as a heat medium.

Structural Form

Maternal Liquid Drying And Evaporation Machine can be divided into two forms: single cylinder, double cylinder dryer. In addition, it can also be divided into two forms of normal pressure and reduced pressure according to the operating pressure.

Installation

Double drum scraper dryer installation system according to the general layout of the installation, the ground should be flat, the steam pipe inlet should be installed at the pressure gauge and safety valve, the steam inlet flange is firmly connected.

Areas of use

Maternal Liquid Drying And Evaporation Machine of the whole product drying is mainly used to deal with liquid materials, which can be heated and dried by steam, hot water or hot oil, or cooled and knotted by cold water: according to different material properties and process requirements, it can adopt immersion type, spraying type, milling auxiliary type and other charging methods.

Adaptation of materials

Maternal Liquid Drying And Evaporation all-in-one machine is suitable for the drying of liquid or more viscous materials in the industries of chemical industry, water purifier, copper sulphate, animal gum, vegetable gum, dye yeast, antimicrobial agent, lactose, starch slurry, sodium nitrite, dyestuffs, distillation waste liquid, sulphide blue, penicillin dregs, wastewater extracted proteins, metallurgy and so on.

Maintenance

(1) Regularly check the rotation flexibility of rotating parts, whether there is any jamming phenomenon. Sprocket and other parts should be regularly added to the grease, regular correction of pressure gauges and other measuring devices error. The triangle belt drive parts should be replaced in time if there is serious wear and tear.

2)Maintenance of motor and reducer is shown in the instruction manual of motor and reducer.

Adjust Components During Testing

(1) After the installation of Maternal Liquid Drying And Evaporation Machine, we should carry out the test run experiment firstly to start the main motor and observe the main drum steering correctly.

(2) Observe the main drum and each transmission parts rotation is flexible, observe the steam import and export is connected, whether the pressure gauge in the working pressure range.

(3) Start the motor, the main drum running smoothly, the temperature rises after joining the material to adjust the motor speed and the material on the drum film uniformity to control the final moisture content of the material.

(4) Start the motor, output dry finished materials, according to the amount of dry finished products to adjust the motor speed.

QUANPIN Dryer Granulator Mixer

YANCHENG QUANPIN MACHINERY CO., LTD.

A professional manufacturer focusing on the research, development and manufacture of drying equipment, granulator equipment, mixer equipment, crusher or sieve equipment.

Currently, our major products include capacity of various types of drying, granulating, crushing, mixing, concentrating and extracting equipment reaches more than 1,000 sets. With rich experience and strict quality.

https://www.quanpinmachine.com/

https://quanpindrying.en.alibaba.com/

Mobile Phone:+86 19850785582

WhatApp:+8615921493205